E-mail:szbldpcb@163.com

Hotline number:0755-26652383

E-mail:szbldpcb@163.com

Hotline number:0755-26652383

PCB Manufacturing has a significant impact on product quality and cost. Therefore, it is important to consider PCB Can manufacturers produce high-quality products from fabrics at a low price PCB。

Almost all electronic devices, from electronic watches and calculators to computers, electronic communication devices, and military weapon systems, use printed circuit boards (PCBs) to electrically interconnect integrated circuits and other electronic components. In the research and manufacturing of a large number of electronic products, the most fundamental success factor is the product's PCB Design and PCB manufacture. PCB Design and PCB Manufacturing affects the quality and cost of products.

IPCB We specialize in developing and manufacturing high-quality products PCB of PCB Manufacturing company. Focused on providing professional services to customers PCB Manufacturing services. iPCB of PCB The manufacturing plant covers an area of 23000 square meters and has 280 employees, of which more than 35% are professional and technical personnel. IPCB Focused on high-frequency microwave PCB、HDI PCB、IC Substrate, rigid and flexible PCB、 multilayer PCB、Rogers PCB、 6th floor PCB Manufacturing and 2-layer PCB manufacture. The product is widely used in industries such as Industry 4.0, communication, industrial control, digital, power supply, computer, automotive, medical, aerospace, instrumentation, and the Internet of Things. Our customers are distributed in China, Taiwan, South Korea, Japan, the United States, Brazil, India, Russia, Southeast Asia, Europe and other parts of the world. exist PCB In terms of manufacturing, ipcb continuous improvement PCB Manufacturing process, solved PCB Technology and PCB Manufacturing issues. ipcb Always adhere to manufacturing high-quality products PCB Product as the purpose. ipcb Adopting advanced technology PCB Equipment and PCB Production line, become the best in China PCB Manufacturing company.

PCB Manufacturing service factory

PCB What is the manufacturing process?

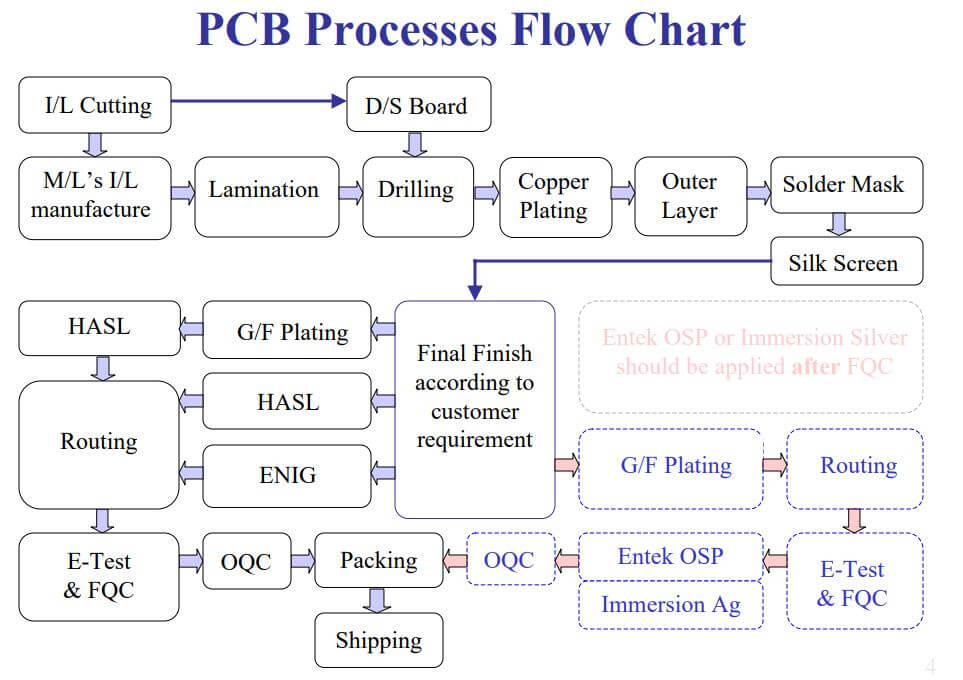

PCB The manufacturing process is more complex. It involves a wide range of functions, from simple mechanical processing to complex automated processing, common chemical reactions, photochemistry, electrochemistry, thermochemistry, and other processes, computer-aided design CAM, And many other aspects of knowledge. In addition, there are many process issues in the production process, and new problems may arise from time to time. Some problems disappear without finding the cause. due to PCB The manufacturing process is a discontinuous assembly line form, and any problem in any link will cause the entire production line to stop production. Alternatively, due to the large amount of waste, if PCB If they are scrapped, they cannot be recycled or reused. The work pressure of process engineers is relatively high, so many engineers have left this industry and turned to PCB Equipment or data suppliers provide sales and technical services.

PCB The substrate is made of insulating material and is not easily bent. Therefore, the small circuit data seen on the surface is copper foil. exist PCB During the manufacturing process, copper foil initially covers the entire circuit board and some parts of the circuit board. After being etched away, the remaining part becomes a mesh like small circuit. These circuits are called conductor patterns or wiring, and are PCB The details provide circuit connections.

To fix the parts in place PCB Above, we solder its pins directly onto the wiring. At the most basic level PCB( On a single panel, the parts are concentrated on one side and the wires are concentrated on the other side. Therefore, it is necessary to make holes on the circuit board so that the pins can pass through the circuit board to the other side, thereby soldering the pins of the parts on the other side. Therefore, PCB The front and back sides are referred to as the component side and solder side.

if PCB If certain parts need to be disassembled or reinstalled after production, sockets will be used when installing the parts. Due to the socket being directly welded onto the board, it can be disassembled and assembled freely.

have sth. to do with PCB For more detailed information on manufacturing processes, please download PCB manufacturing process PDF-PCB manufacturing process PDF。

PCB manufacturing process

In the electronic product processing industry, PCB A board is one of the indispensable key electronic components. PCB There are various types of boards, such as high-frequency ones PCB Plate, microwave heating PCB Printed circuit boards of various types enjoy a special reputation in the sales market. PCB The manufacturing company has unique manufacturing processes for each sample. But generally speaking, in PCB The following three factors must be considered in the production and processing of boards.

1.PCB Board selection

PCB The board can be divided into organic chemical data and inorganic data. Each raw material has its unique advantages. Therefore, PCB The type of board needs to take into account the following factors: the performance of the dielectric gas, the type of copper foil, the thickness of the substrate, production and processing characteristics, etc. Among them, the surface thickness of copper foil is a hazard PCB The primary condition for characteristics. Generally speaking, the thinner the thickness, the more convenient the etching process and the higher the level of drawing accuracy.

2.PCB Setting of manufacturing process PCB The natural environment of the manufacturing workshop is a crucial aspect. In addition, the control of working temperature and relative humidity of the air is also an important factor. If the working temperature conversion is too obvious, it may cause the plate on the rotating hole to break. On the other hand, if the relative humidity of the air is too high, the performance plane of the dielectric gas shows that nuclear power generation poses a terrible hazard to plates with solid water absorption capacity. Therefore, in PCB It is necessary to maintain appropriate natural environmental standards during the manufacturing process.

3.PCB Selection of production process

PCB Manufacturing is highly susceptible to damage from various components. The production and processing processes, such as layers, collapse processing techniques, and surface coating solutions, may have an impact on PCB The quality of the finished product has caused damage. Therefore, in the natural environment of this production process, PCB Manufacturing is carried out by integrating the characteristics of manufacturing machinery and equipment. Considering this, it can be adjusted according to different factors PCB Flexible adjustment of board types and production processing requirements. Generally speaking, PCB Manufacturing must consider the selection of sheet materials, production process settings, and the choice of production processes. In addition, PCB The solution for constructing data on the board and opening the data pipeline is a level that must be carefully selected, which is closely related to the glossiness of the finished power circuit packaging printed board.

PCB What are the common errors in manufacturing and how can they be avoided?

1. Overlapping of welded plates.

a. During the drilling process, multiple fractured and damaged large holes are formed in one location.

b. In multiple layers PCB In the board, the connecting board and the isolation board are located in the same position. Therefore, PCB The board displays isolation and connection errors.

2. Improper use of graphics layer

a. Violating conventional designs, such as the surface design of bottom level components and the welding surface design of top level, is misleading.

b. Each layer has a lot of design junk, such as broken lines, useless borders, labels, etc.

3. Unreasonable personality

A.SMD The characters on the welding plate will be given PCB The switch detection and component welding cause inconvenience.

b. The characters are too small to be screen printed, and too large to overlap and distinguish. The font is usually larger than 40 mil。

4. Set the aperture of a single welding plate

a. Single sided welding plates generally do not have holes, and their aperture should be designed to be zero; Otherwise, when generating drilling data, the coordinates of the hole will appear at that location. Special instructions should be provided for drilling.

b. If it is necessary to drill holes on a single-sided pad without a designed aperture, the software will consider the pad as SMT Solder pads. Therefore, the isolation board will be lost in the inner layer.

Which files are sent to PCB manufacturer?

If you want to obtain PCB You must consider the manufacturing cost PCB Specifications sent to PCB manufacturer. If you need PCB Manufacturing, please provide the original PCB Archives, such as (flies. PCB, flie. docPCB) or Gerber Archives and PCB Send manufacturing drawing annotations to PCB manufacturer.

PCB The manufacturing drawing instructions should specify PCB Manufacturing quantity PCB Thickness, copper thickness PCB Color, surface treatment, and how to assemble PCB Copy, how to deliver, required delivery date, etc.

If you don't have PCB Examples of manufacturing instructions, ipcb I have already prepared one for you PCB Examples of manufacturing drawings; Please click to download PCB Example of Manufacturing Instructions- PCB Example of wafer fab description.

IPCB Passed ISO9001、UL、RoHS Waiting for quality control system certification. Our production line adopts imported precision circuit board manufacturing and testing equipment, and has a team of experienced professionals PCB The manufacturing technology team has established a comprehensive assurance system and strict quality control. PCB Strictly follow ipcb Secondary standard or IPC Third level standard manufacturing to ensure PCB Meet the customer's quality requirements. In addition, the company advocates the principle of "doing our best and prioritizing prevention" PCB The quality concept has been improved PCB The efficiency of manufacturing saves costs and working time, providing customers with the best PCB Manufacturing services.

IPCB It's a family PCB Manufacturing professional manufacturers; You can apply here PCB Manufacturing quotation. please contact ipcb Or will Gerber Archives and PCB Send the manufacturing drawing instructions to ipcb。 We will get back to you soon.